Flashings Stratco NZ

Roof flashing - Placed around discontinuities or objects which protrude from the roof of a building to deflect water away from seams or joints and in valleys where the runoff is concentrated. Wall flashing

Guide to Roof Flashing Installation, Roof Flashing Repair & Types IKO

Flashings play a vital role in keeping water out of buildings. Follow this useful guide to check the requirements for roof flashings in Acceptable Solution E2/AS1. THE TYPE of roof flashings required depends on what part of the roof is being flashed and what the roofing material is. Apron flashings Horizontal apron flashings must:

Roof flashings BRANZ Build

How to cut lead flashing Here at Roofing Superstore, we offer a cut-to-size service for your lead flashing requirements, allowing you to minimise time and labour spent on cutting lead flashing on-site, as well as minimising waste.

Lead flashing on pan tile roof Stock Photo Alamy

A lap is the part of a flashing that covers (or overlaps) any part of the similarly shaped component, and these can be described as an end lap, overlap or underlap. Laps should comply with the following criteria: • an overlap must run over (not under); • an overlap must run downhill (the direction of the water flow);

Learn the Lingo Roof Flashing Aspen Contracting

2.6 MAXIMUM LENGTHS OF ROOFING The valleys (or pans) of roofing have to carry water to the gutters. If the valleys overfill in heavy rain, water can flow into the roof through the side-laps and flashings. Factors affecting waterproof and drainage capacity of the laps of a profile include: • the width and depth of the valleys or pans;

Pitch Pan (Pitch Pocket) • Roof Flashing Explained

The copper roofing pans are turned up on the vertical wall to form a base flashing extending at least 9" up the wall where they are cleated. Copper flashing, held by a receiver at the top, is locked into a locking strip soldered to the base flashing. The counterflashing overlaps the base flashing by at least 4".

Roof Flashing Inspection Gallery InterNACHI®

Roof Materials Expenses Associated with Flashing Installations and Repairs. The national average cost to hire a roofer to replace the flashing, shingles, and to seal a leak in a small area of the roof is between $300 and $1,100. Larger roof fixes can cost between $1,100 and $1,500+. New Shingle Roof.

Pitch Pan (Pitch Pocket) • Roof Flashing Explained

Roof flashing is basically a thin material - typically galvanized steel - that professional roofers will use in order to direct water away from the critical areas of the roof. Typically, it is wherever the roof plan meets a vertical surface, like a dormer or a wall. Roof Flashing Types Continuous Base Counter Step Skylight Valley Drip Edges Kickout

Flashing —

Roof flashing is a thin material, usually galvanized steel, that professional roofers use to direct water away from critical areas of the roof, wherever the roof plane meets a vertical surface like a wall or a dormer. Flashing is installed to surround roof features, such as vents, chimneys and skylights.

Ultimate Guide To Roof Flashing

to all pans of the roof sheet to avoid flooding of the laps. • Can be ordered in kit form, off a plan, months in advance. • No site measure is required, saving time on site.. roof penetration. DRY PAN FLASHING AT 175MM PER HOUR RAINFALL INTENSITY 7 All water directed to adjacent pans, well and

Flashing

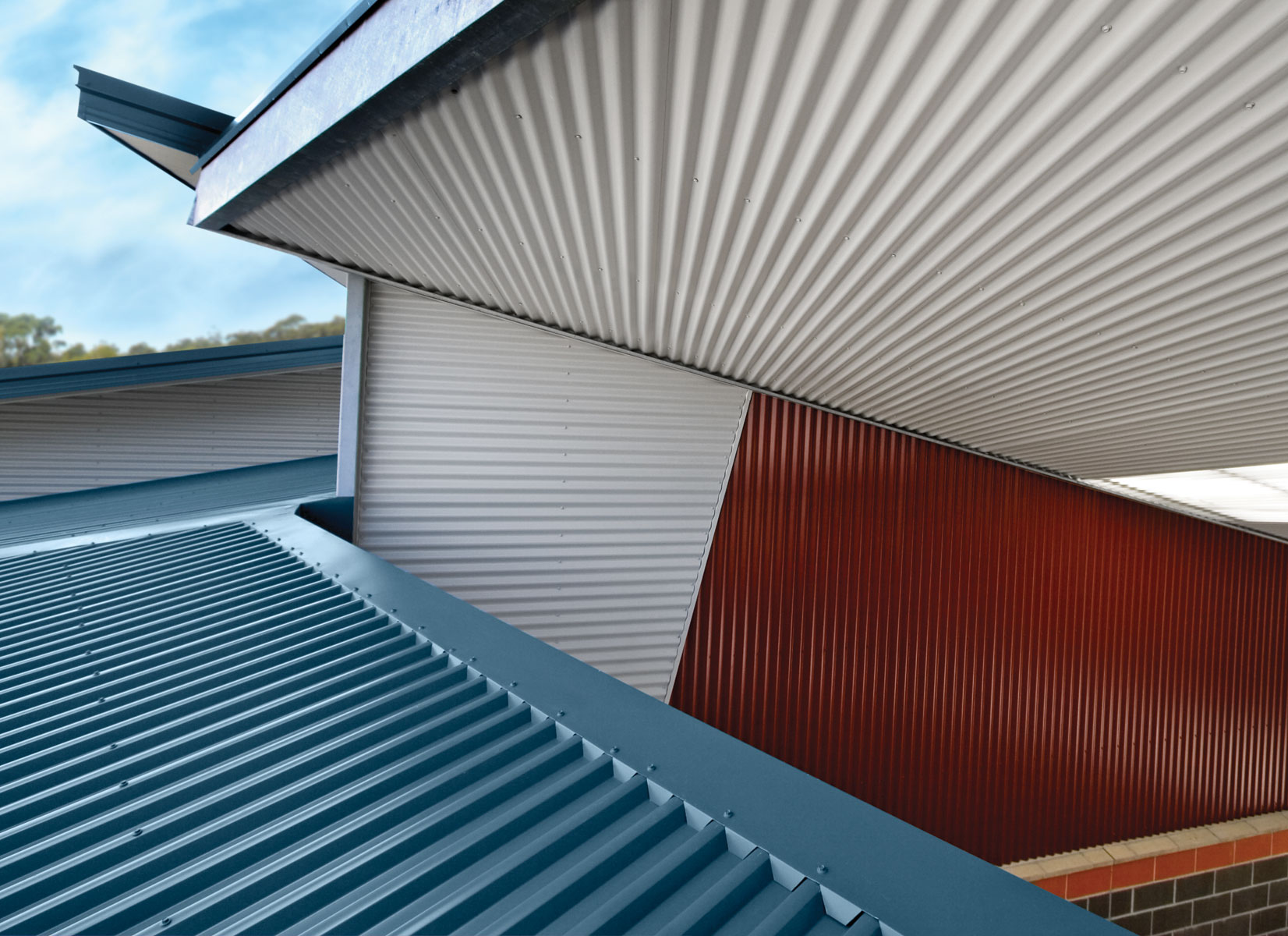

Tapered flashings that drain at the plane of the roof pan at the top, and over the ribs at the bottom. Also known as transition or 'under/over' flashings. Tapered or transition flashings • Provides greater water run-off capacity • Suitable for all roofs > 5°. • Can be used for a retrofit • Support required Type D

Types of Roof Flashing Evergreen Construction Company Inc.

Material In wood framed openings the pan flashings may be fashioned in the field from self-adhered flashing membrane, self-adhered formable flashing, non-water-sensitive sheet metal and certain liquid-applied waterproof membranes. Manufactured pan flashing may also be used to drain the opening.

How To Properly Install Roof Flashings Oatey

A pitch pocket is a type of roof flashing for small or irregular roof penetrations. Pitch pockets look like boxes, rings, or cylinders made out of sheet metal (normally galvanized steel) or a pre-molded polymer. Although they are usually open at the top, some specifiers require pitch pockets to have covers on them for added weather protection.

Roof flashings BRANZ Build

The pitch pan corners should have a 2-inch radius and are lapped a minimum of ½ inch. There should be a minimum 4-inch flange at the perimeter of the pan that serves as a base over the membrane surface. The membrane should be set to the opening with manufactured-approved flashing applied at the perimeter of the pitch pan covering the flange.

Roof replacement cost Leaf guard gutters cost Affordable roofing Logan, Ipswich, Beaudesert

Roof penetration system. Unlike unattractive and poorly performing dry pan flashing, the patented Pop Up Penetration™ system, exclusively distributed by Lysaght, facilitates the even flow of rainwater where roof penetrations are located thanks to a unique and elegant design which ensures a long run roof carries water away evenly and efficiently.

What Is Roof Flashing? DIY Home Improvement

The RDP Tile Pan Flashing is a transition flashing, that means it is most commonly used in side wall or end wall applications. It is a really great way to prevent water infiltration on those intersections. The RDP Tile Pan Flashing is made with heavy duty, 28 gauge, galvanized steel.